- Tool Holder

- Collet

- Pull Studs

- End Mills

- Insert

- Accessories

- High Speed U drills

- Lathe tools

- Milling holder

- PCD/CBN inserts

Latest news

- Our milling insert testing case

- HRC65 Flat end mills introductions

- HRC55 Endmills Features

- WDMW080520 testing case

- Cooperated Area

- Ball endmill features

Contact us

- ADD: Room 701,Bldg 11,lane 1,Cuigang zone 1, Fuyong Town,Bao'an District, Shen Zhen,518103,China

- TEL: +86-0755-27207379

- FAX: 0755-27207379

- E-mail: ailsa@seayac.com

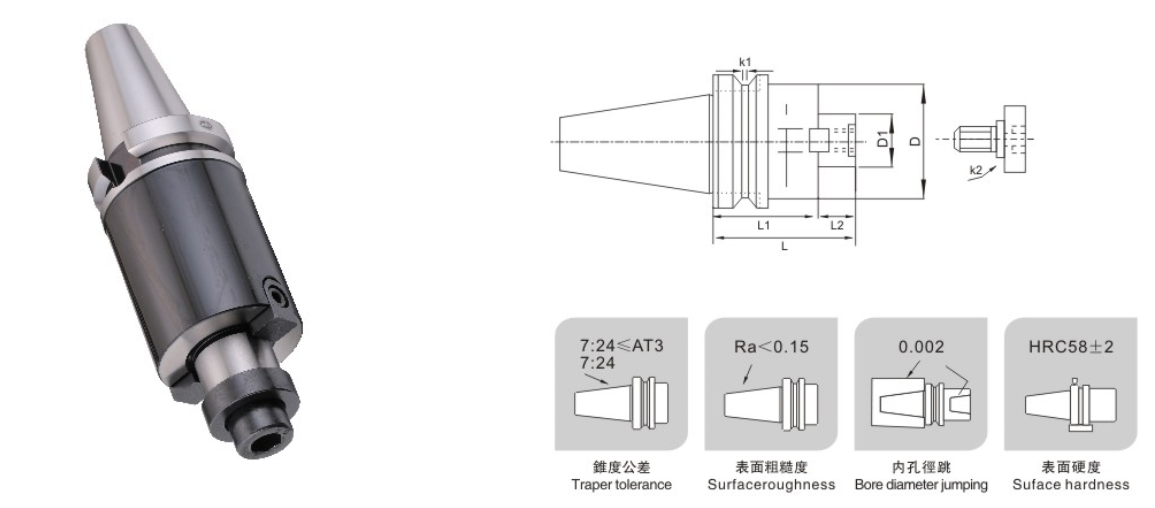

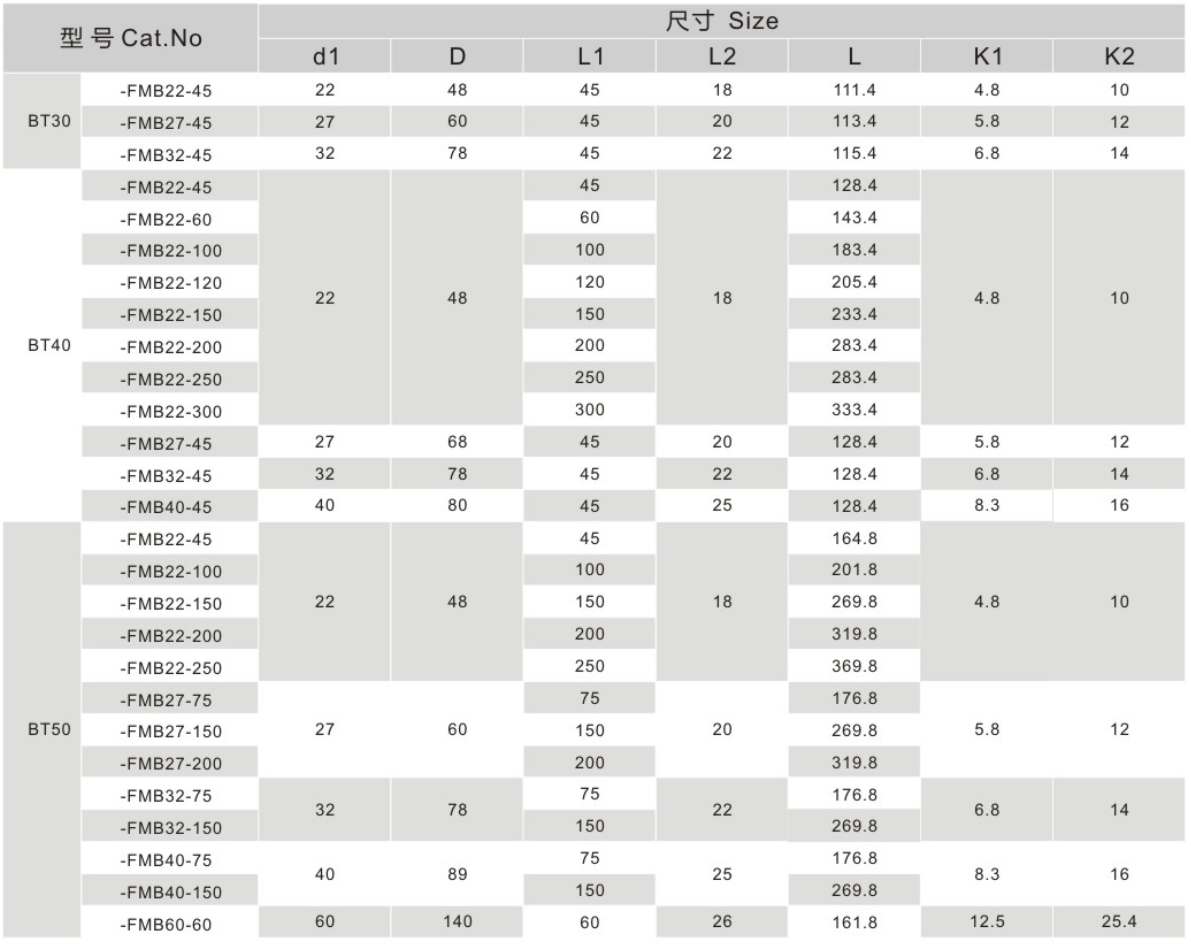

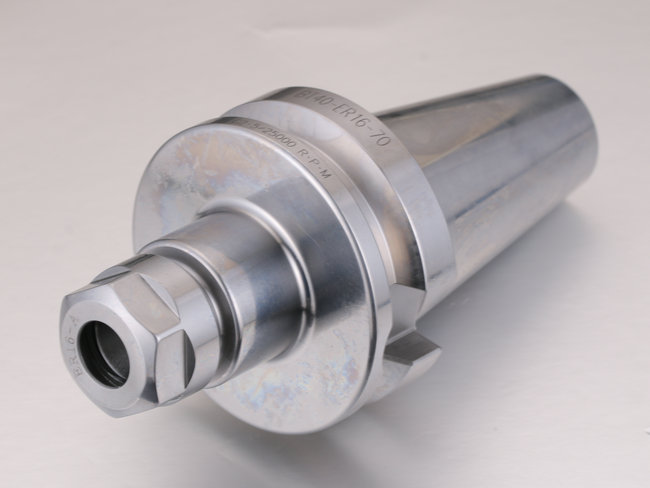

High precision Face Mill Holder

- Material:20CrMnTi

- Hardness:58+/-2HRC

- Tolerance

- Product description: Carbon depth:>0.8 Surface roughness:Ra<0.4μ.

Product introduction

High precision FMB/FMA Face Mill Holder

Comprehensive

1.激光标识

在刀具上精确可视标记不平衡位盖

Laser marking

exact optical marking of the

unbalance positions on the tool

2.预调

测量系统具有高分辨率摄像

机且可进行数字图像处理

Presetting

Measuring system with high

resolution camera and digital

photo processing

features of CNC Chucks

Materia1:20CrMnTi;

Hardness:58士2HRC;

7:24 Tapper tolerance≤AT3;

Carbon depth>0.8;

Surface roughness:Ra<0.4u;

Provide 2 kinds appearance;Sand一blasting and Electroless plating process;

Sub-zero treatment:

All of the CNC chucks are processed long time

sub-zero treatment(-180℃,mare than 20 hours) Make the residual austenite into martensite and precipitate of nano-sized carbide particLes,enhance chucks hardness.

toughness durability,and reduce the residual internal stress.

Thermal aging treatment:

Long time thermal aging treatment can get rid of the residual

interna stress in grinding process.

Phoebe Liu

Phoebe Liu