- Tool Holder

- Collet

- Pull Studs

- End Mills

- Insert

- Accessories

- High Speed U drills

- Lathe tools

- Milling holder

- PCD/CBN inserts

Latest news

- Our milling insert testing case

- HRC65 Flat end mills introductions

- HRC55 Endmills Features

- WDMW080520 testing case

- Cooperated Area

- Ball endmill features

Contact us

- ADD: Room 701,Bldg 11,lane 1,Cuigang zone 1, Fuyong Town,Bao'an District, Shen Zhen,518103,China

- TEL: +86-0755-27207379

- FAX: 0755-27207379

- E-mail: ailsa@seayac.com

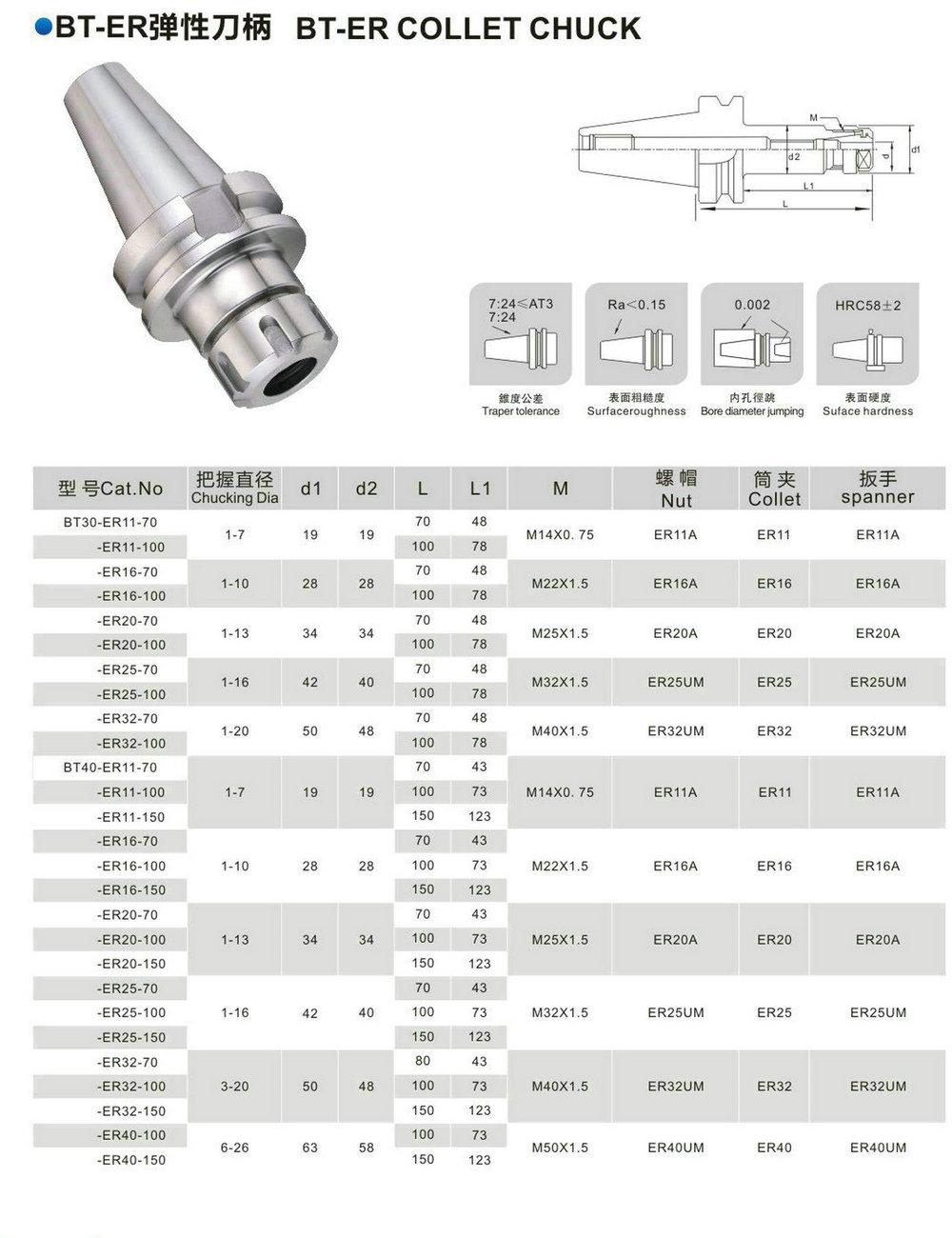

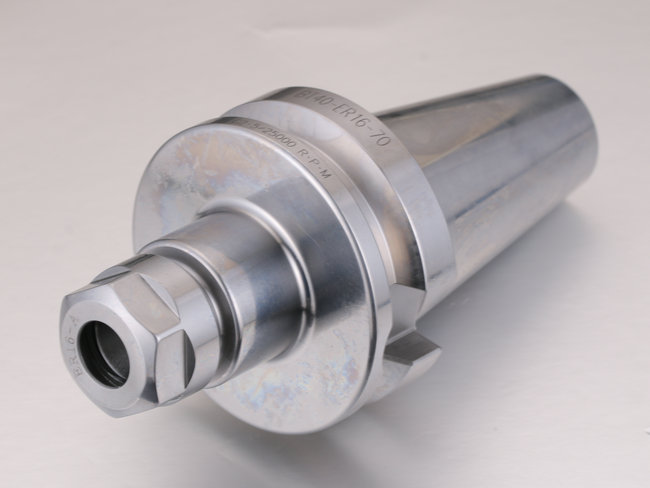

BT30 Taper Er Collet Chuck

- Standard:MAS403/BT

- Material:20CrMnTi

- -185° long cryogenic treatment

- Product description: BT30-ER32-60 Ra<0.15 7:24≤AT3 Hardness:HRC56-60°

Product introduction

USE:

For clamping tools with cylindrical shank in Collets according to DIN 6499;

Comprehensive inspection way of chuck

#7:24 taper precision ≤AT3And part of the standard size are tested by

standard inspection tools which made in Germany;

#Surface of the clamping inner hole is grinding by high speed inner-aperture grinder. and inspect by standard pneumatic measurement instrument; the big end contact area rate is above 90%;

#Shank thread is inspected with 4h level thread ring gauge. and the nut is inspected with 4H level thread plug gauge, the quality guaranteed;

#Run out of the inside shank Bone: <0.002(The length of the shank 100L)

#Coaxiality 5u:Shank run out≤0.002;

Equip≤0.005. The highest comprehensive run out point is no more than0.005(≤0.005mm collet clamping interchangeable with any integrated shank run out does not exceed the highest accuracy 0.008mm);

#Dynamic balance:We can do G2.5 20000一50000rpm according to clients demands.

Cryogenic treatment

1.-185℃ long cryogenic.nearly all of the residual austenite into martensite

2.Carbide precipitation of Nanoscale particles,increasing the hardness

and toughness 3.Reducing residual stresses

4.Wear resistance significantly improved

#20h超长定型热时效去除磨加工时的残余内应用力

Thermal aging processing

20h long stereotyped thermal limitation removal

of grinding residual of grinding residual stress.

Phoebe Liu

Phoebe Liu